Technologies Accepted for use in Nassau County’s S.E.P.T.I.C. Program

The Nassau County Conservation District has developed a stringent and tiered Acceptance Process to provide program applicants with a list of proven nitrogen-reducing technologies, as well as help system manufacturers who are looking to submit their technologies for use in Nassau County. The list of Accepted Technologies can be found below, in addition, you can download this list with additional resources for Designers, Installers, and Program Applicants.

How do these Technologies Reduce Nitrogen?

The technologies listed above all utilize biological processes to treat wastewater and remove nitrogen. These systems use various methods to provide aerobic bacteria to convert organic nitrogen to nitrite and nitrate and then use an anaerobic (without oxygen) environment to denitrify by stripping the oxygen molecule off the nitrate nitrogen, resulting in the release of gaseous nitrogen into our atmosphere. The nitrogen cycle is one of Earth’s most important biological processes, second only to photosynthesis.

Acceptance Process Resources for IA OWTS Distributors and Manufacturers

Nassau County’s S.E.P.T.I.C. Grant Program - Accepted Technologies

Technologies Accepted for General and Provisional use

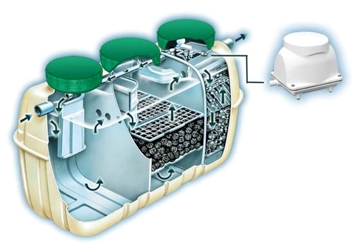

Fuji System CEN Series

The Fuji Clean system treats wastewater through a process of contact filtration, flow equalization and recirculation, all within one tank consisting of three sequential “Sedimentation,” “Anaerobic” and “Aerobic” chambers.

Long Island Distributor Information:

Bryan McGowin

Advanced Wastewater Solutions, LLC

PO Box 1622 Southampton, NY 11969

Phone: (631) 259-3353

www.awsli.com

bmcgowin@gmail.com

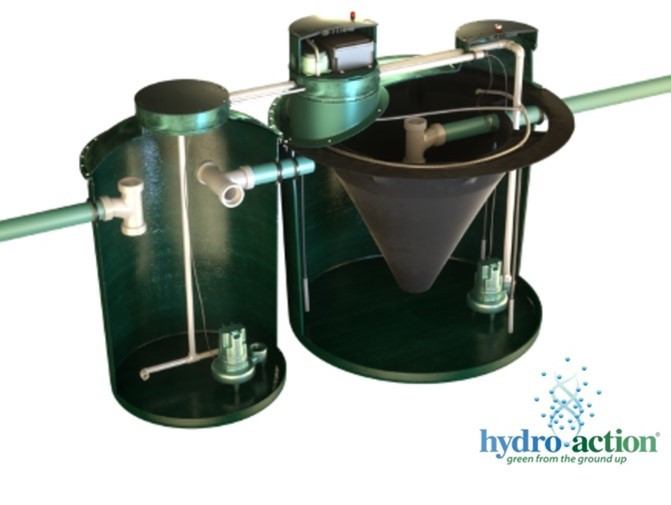

Hydro-Action AN Series by AK Industries Inc.

Hydro-Action AN Series by AK Industries Inc: The Hydro-Action® system utilizes a suspended growth aeration system. The treatment occurs as wastewater enters the pretreatment tank and flows by gravity into the aeration compartment. The aerobically charged wastewater is then recirculated back to the pretreatment tank for denitrification. Treated wastewater exits by gravity through a tee structure located in the center of the clarifier, and treated effluent is then discharged to the leaching structure.

Long Island Distributor Information:

Joe Densieski

Wastewater Works Inc.

139 Reeves Avenue, Riverhead, NY 11901

www.wastewaterworksinc.com

wastewaterworks@gmail.com

SeptiTech STAAR

SeptiTech® STAAR™ (Smart Trickling Anaerobic/Aerobic Recirculation) System treats high organic loads by utilizing biological trickling filter technology. Influent first enters a two-compartment, settling tank to allow separation of solids from liquids. Effluent from the primary settling tank flows through an effluent filter into the treatment tank at the bottom of the trickling filter mixing with the treated wastewater. Wastewater is then pumped up into the trickling filter. The pump simultaneously draws a robust amount of air. Wastewater is pumped back to the settling tank for denitrification.

Long Island Distributor Information:

John Lindahl

SeptiTech Long Island

27 Service Rd A

Calverton, NY 11933

(631) 284-9893

Advantex AX Series by Orenco Systems Inc.

Orenco's Advantex AX System is a prepackaged packed bed media filter consisting of a proprietary textile media, that reduces BOD and TSS. The AX unit is housed inside a fiberglass container and installed after a two-compartment tank prior to discharge to a leaching structure. When configured in recirculation mode (mode 3), this system reduces nitrogen by returning the treated nitrified wastewater to the septic tank, where denitrification occurs and nitrate is converted to nitrogen gas.

Long Island Distributor Information:

Lee Essay, Nugent & Potter

1557 County Road 39 Southampton, NY 11968

Lee@nugentpotter.com

www.nugentpotter.com

(631) 283-1103

HydroKinetic by Norweco Inc:

The HydroKinetic system by Norweco uses extended aeration, attached growth, nitrification, and denitrification processes to treat wastewater. It consists of four treatment chambers (pretreatment, anoxic, aeration, and clarification) followed by a Hydro-Kinetic FEU filter containing filter media facilitating additional reduction of BOD and TSS by attached growth, prior to discharge to a leaching structure.

Long Island Distributor:

Norweco of New York

2065 Pond Avenue

Ronkonkoma, NY 11779

contact@norwecony.com

(516) 710-7967

Technologies Accepted for Piloting use

* Limited to 12 installations per technology in Nassau County

Lined Nitrogen Reducing Biofilter (NRB)

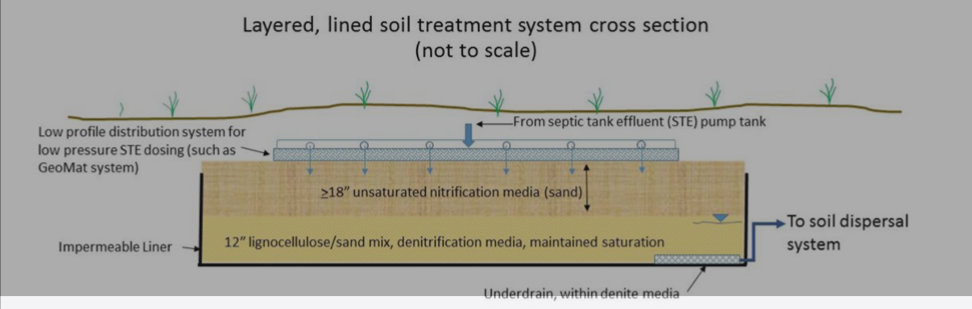

The Center for Clean Water Technology has prepared numerous technical and scientific papers on Nitrogen-Removing Biofilters (NRBs) theory and process. NRBs generally consist of a nitrifying sand layer placed over a denitrifying mix of sand and lignocellulose. NRBs are relatively passive systems, utilizing a pump to dime-dose the field built filter, which is constructed with locally available material. NRBs are relatively passive systems with limited mechanical parts.

Long Island Contact:

Frank M. Russo, P.E.

Associate Director for Wastewater Initiatives

NYS Center for Clean Water Technology at Stony Brook University

BioCoir Coconut Fiber Biofilter by Anua

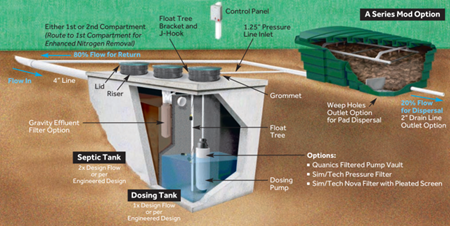

BioCoir is a modular recirculating biofilter that utilizes sustainable fibers sourced and upcycled from coconut husks housed in a preassembled module (mod). The mods are factory assembled and can be configured as a combined treatment and effluent pad dispersal system or as a dispersal and polishing filter following other IA OWTS Treatment Systems.

Long Island Contact:

Anua

Colin Bishop, CEO

Government Relations Specialist

T: 928.433.3220

colin.bishop@anua-us.com

ECOPOD-NX by Infiltrator Water Technologies

The ECOPOD-NX utilizes fully submerged moving bed biofilm reactor (MBBR) media housed in a specially designed reactor box and utilizes air-lift recirculation of nitrified effluent from the reactor tank to the pretreatment tank to augment denitrification effectiveness. The MBBR media is contained within the reactor box by a polypropylene grid affixed near the top and the bottom of the reactor box. A single aerator provides air to both the air lift and air distribution system.

Long Island Distributor Information:

Lee Essay, Nugent & Potter

1557 County Road 39, Southampton, NY 11968

Lee@nugentpotter.com www.nugentpotter.com

(631) 283-1103

ECOPOD-Edge by Infiltrator Water Technologies

The ECOPOD-Edge utilizes fully submerged fixed film media housed in a specially designed reactor to treat wastewater. The system is integrated within Infiltrator’s CM-1060 tank and incorporates two compartments containing a total of four process unit operations within four distinct treatment zones to reduce effluent concentrations of CBOD5, TSS, and Total Nitrogen to levels below those required by Standards 40 and 245. A summary of the NSF/ANSI 245 sample results is included in Table 1.

Long Island Distributor Information:

Lee Essay, Nugent & Potter

1557 County Road 39, Southampton, NY 11968

Lee@nugentpotter.com www.nugentpotter.com

(631) 283-1103